Professional Manufacturer

Helical Gearbox

About

Helical Gearbox

“Dedicated to Helical Gearbox Excellence.We also have a large onsite stock of replacement parts for our helical gearboxes and helical bevel gearboxes which can be shipped out whenever the need arises.”

– HEPT

Experience

About HEPT

Years of experience

R & D personnel

satisfied customers

Advantages of Helical Gearbox

Applications of Helical Gearbox

helical gearbox

Featured Products

Gearbox

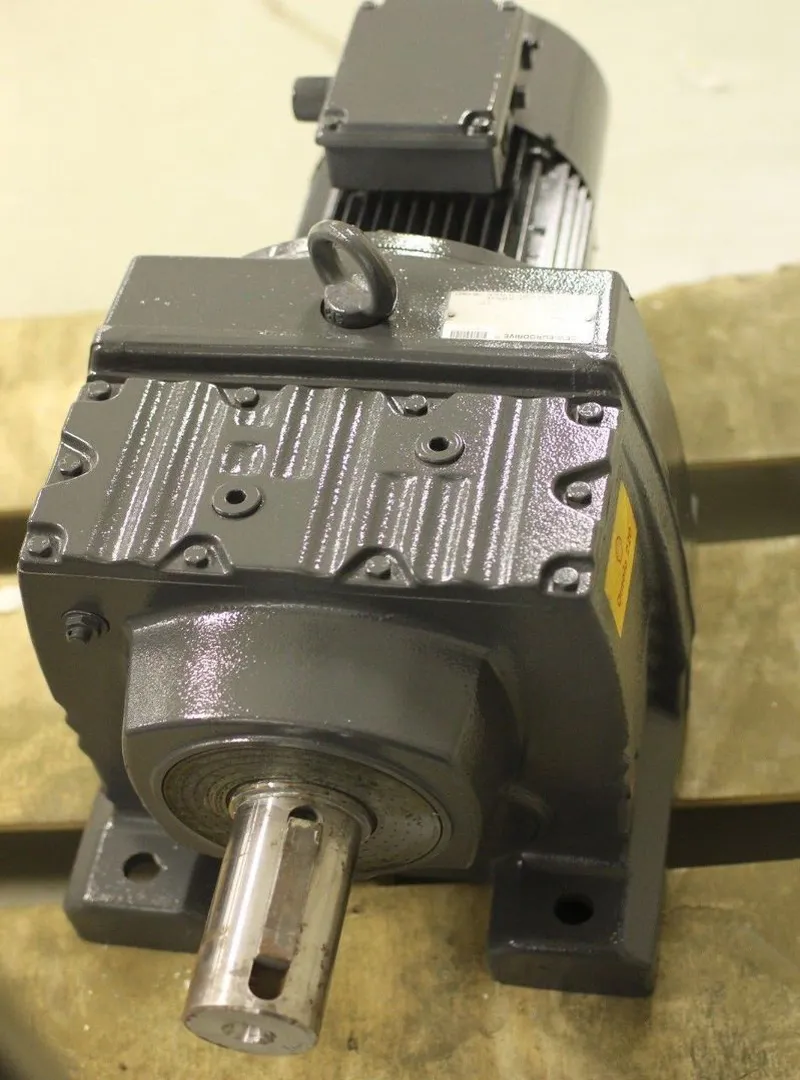

Series G : Helical Gearbox

Gearbox

Series HB: Bevel Helical Gearbox

Gearbox

Series S: Helical Worm Gearbox

Gearbox

Series R : Inline Helical Gearbox

Gearbox

Series F: Parallel Shaft Helical Gearbox

Gearbox

Series K : Helical Bevel Gearbox

K series

helical gearbox

When possible, do not use a vertical installation. When installing vertically, the amount of lubricating oil added is much more than that of horizontal installation, which may cause heat generation and oil leakage of the gearbox.

application

Mining Industry

application

Printing and Packaging

application

Conveyor

Lubrication maintenance

The gearbox can be maintained according to the “five-set” principle of lubrication work. Every gearbox has a responsible person to check regularly and find that the temperature rise is obvious. If the temperature exceeds 40°C or the oil temperature exceeds 80°C, the quality of the oil will drop or oil. When more copper powder is found and abnormal noise is generated, stop using it immediately, repair it in time, troubleshoot it, and replace the oil. When refueling, pay attention to the amount of oil to ensure that the gear unit is properly lubricated.

(1) Space-saving, reliable and durable, with high overload capacity and power up to 132KW;

(2) Low energy consumption, superior performance, R series helical inline Coaxial helical inline gearbox efficiency as high as more than 95%;

(3) Low vibration, low noise, high energy saving;

(4) Select high quality forged steel materials, steel cast iron box body, and gear surface through high-frequency heat treatment;

(5) After precision processing, to ensure the shaft parallelism and bearing positioning requirements, the gearbox is forming the helical gear transmission assembly is equipped with various types of motors, which are combined into electromechanical integration, ultimately guaranteeing the product quality characteristics.

Contact Me

Why HEPT Helical Gearboxes?

Gearbox

Some FAQ

Q: How to choose a gearbox that meets our requirements?

A: You can refer to our catalog to choose the gearbox or we can help to choose when you provide the technical information of required output torque, output speed and motor parameter,s etc.

Q: What information shall we give before placing a purchase order?

a) Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor information etc.

b) Housing color.

c) Purchase quantity.

d) Other special requirements.

Q: How to maintain the gearbox?

A: After a new gearbox is being used about 400 hours or 3 months, the lubrication needs to be changed. Afterthat, the oil changing cycle is about every 4000 hours; please do not mix-use different brands of lubrication. It should keep enough amount of lubrication in the gearbox housing and check it regularly. When it is found that the lubrication is deteriorated or the amount is decreased, the lubrication should be changed or filled up in time.

Q: What should we do when the gearbox is breakdown?

A: When the gearbox is breakdown, do not disassemble the parts first. Please contact the relative sales representative at our Foreign Trade Department and provide the information shown on the nameplate, like gearbox specification ans serial number; time used; fault type as well as the quantity of problemed ones. Finally take the appropriate action.

Q: How to store the gearbox?

a) Protected against rain, snow, humidity, dust and impact.

b) Place wood blocks or other material between the gearbox and ground.

c) The opened but not used gear units should be added with the anti-rust oil on their surface, and then return back to the container in time.

d) If the gearbox has been stored for 2 years or even longer time, please check the cleanliness and mechanical damage and whether the anti-rust layer is still there during the regular check-up.

Q: What should we do when unusual and even noise occurs during the gearbox running?

A: It is properly caused by the unevenly mesh between gears or the bearing is damaged. The possible solution is to check the lubrication and change bearings. Moreover, you can also ask our sales representative for further advise.